Complete Cement Plant Solutions

Learn MoreGlobal experience with environmental and alternative fuels project upgrades

Mining Engineering and EPCM Solutions

Learn MoreProfessional services solutions to the mining, metals, and mineral processing industries

Coal Combustion Residuals Beneficial Use Solutions

Learn MoreBeneficiation, material handling and storage systems for fly ash from impoundment to end user

Logistics Expansion and Optimization Solutions

Learn MoreImport and inland design/build bulk material handling systems

Alternative Fuel Solutions

Learn MoreImplementation of alternative fuels systems to reduce carbon emissions

Association Memberships

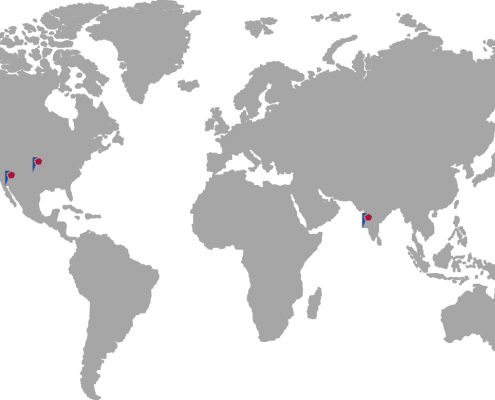

Corporate Headquarters

10123 Corporate Square

St. Louis, MO 63132 USA

Western United States Office

5151 E Broadway Blvd, Suite 1600

Tucson, AZ 85711

India Office

Office No. 6,7 & 8, Hermes Atrium, Plot 57, Sector-11,

CBD Belapur, Navi Mumbai 400614, INDIA