PROCESS & ENVIRONMENTAL ENGINEERING

The Process and Environmental consultants have extensive process knowledge of cement, lime, frac sand, coal and other minerals and available control technologies which enables us to provide an exceptional, unique value to our customers. Our focus is to satisfy specific client requirements with creative, cost-effective solutions. These solutions are developed by a staff with over 100 years of combined experience in plant operations and process design.

PROCESS ENGINEERING

| Engineering Studies | Flow Diagram Development |

| Mine and Quarry Planning | Operations Analysis and Planning |

| Heat and Mass Balances | Process Review Assistance |

| Plant Audits and Optimization | Equipment Selection Assistance |

| Waste Heat Recovery | Material Storage Optimization |

| Alternative Fuels | Operations Analysis |

PROCESS ENGINEERING SERVICES:

- Feasibility studies for plant upgrades, expansions, and Greenfield plants

- Development of plant & system concepts

- Evaluate OEM’s individual schemes and integrate into a seamless global scheme for the entire plant

- Process selection and equipment analysis

- Equipment and process specifications

- Flow diagram development with heat and material balances

- Process control loops for interlocking

- Operations analysis and planning

- Raw materials evaluations and selection

- Analysis of production and shipping patterns to optimize clinker and cement storage requirements

- Kiln feed mix design for cement clinker

- Plant audits to improve efficiency

- Startup and commissioning assistance

- Field assessment of combustion systems

ENVIRONMENTAL ENGINEERING SERVICES

-

- Evaluation/Selection of Optimum Technologies for mitigation of emissions

- NESHAP Compliant Designs

- Emission Reduction and Control (BACT and MACT)

- Development of Control Strategies

- Emissions Control Systems

- Equipment Specifications based on most current Environmental Regulations

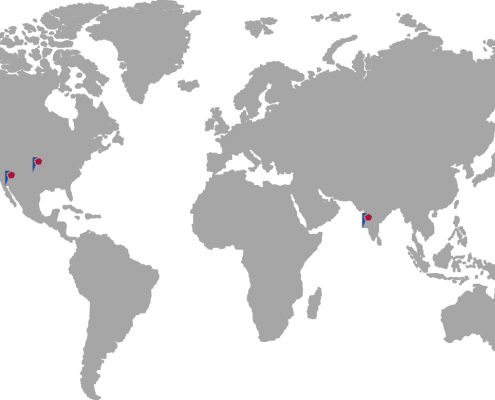

Corporate Headquarters

10123 Corporate Square

St. Louis, MO 63132 USA

Western United States Office

5151 E Broadway Blvd, Suite 1600

Tucson, AZ 85711

India Office

Office No. 6,7 & 8, Hermes Atrium, Plot 57, Sector-11,

CBD Belapur, Navi Mumbai 400614, INDIA