ENGINEERING DESIGN

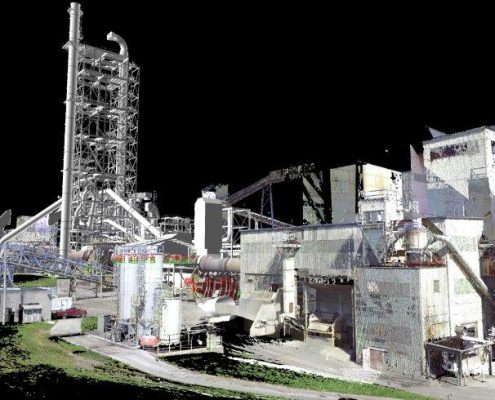

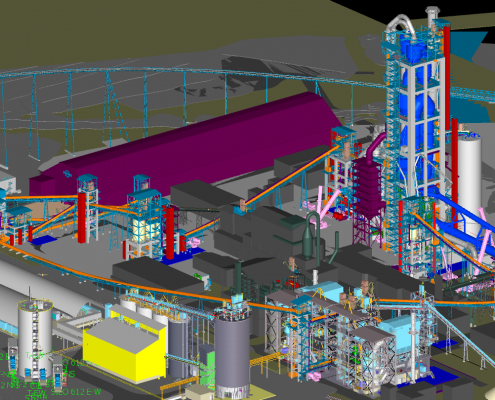

The core business of PENTA is in the engineering of heavy industrial facilities. PENTA is composed of a highly experienced multi-disciplinary team covering:

- Mechanical Engineering Design

- Structural / Civil Engineering Design

- Electrical Engineering Design

- Process & Environmental Engineering

- Mining Engineering

- Why PENTA?

PENTA has been supplying smart and practical plant engineering design for upgrades, modifications, and Greenfield facilities since 1986. We work closely with Customers to fully understand not only the project requirements, but also business and operational goals. Once we have a clear understanding of our Customers metrics for success, we deploy our in-house, multi-disciplinary engineering team to design smart solutions that will achieve successful project outcomes.

“Congratulations on PENTA’s 30 year anniversary. Monarch has a long-standing relationship with PENTA Engineering since 1988. PENTA has provided effective engineered solutions on numerous projects for Monarch Cement from that first project in 1988 to our latest upgrade to our Limestone Unloading System in 2016. We continue to use PENTA Engineering because of the service and dedication to providing the best and most economical solutions for The Monarch Cement Company.”