Insights

PENTA

Project Case Studies

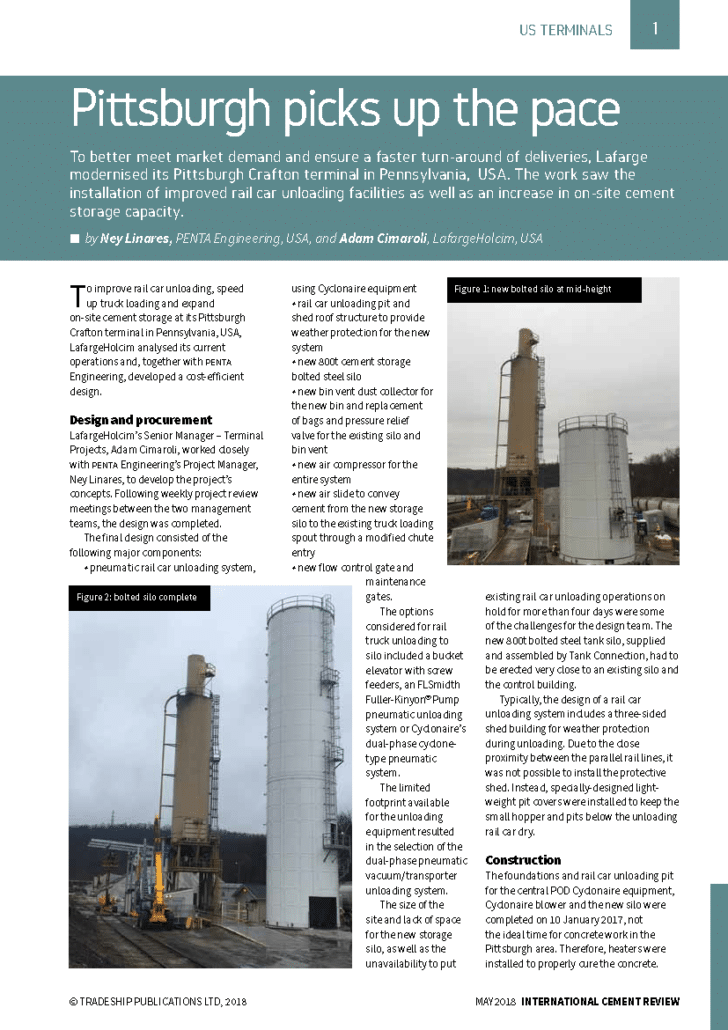

Upgrade Project in collaboration with Owner’s Project Team

Modular system utilization in Terminal Projects

Fast Track Schedule Project Execution

Terminal Automation Solutions

Waste Water Treatment Project as part of a Liquid/Dry Bulk Terminal Project

PENTA

Technical Insights

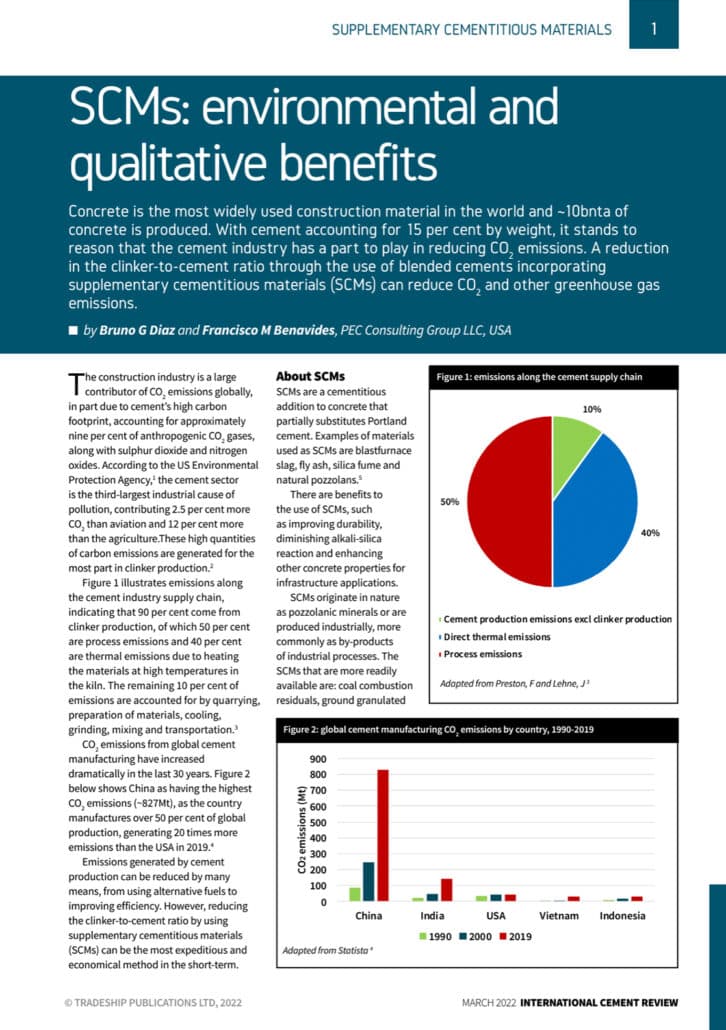

Supplementary Cementitious Materials Utilization

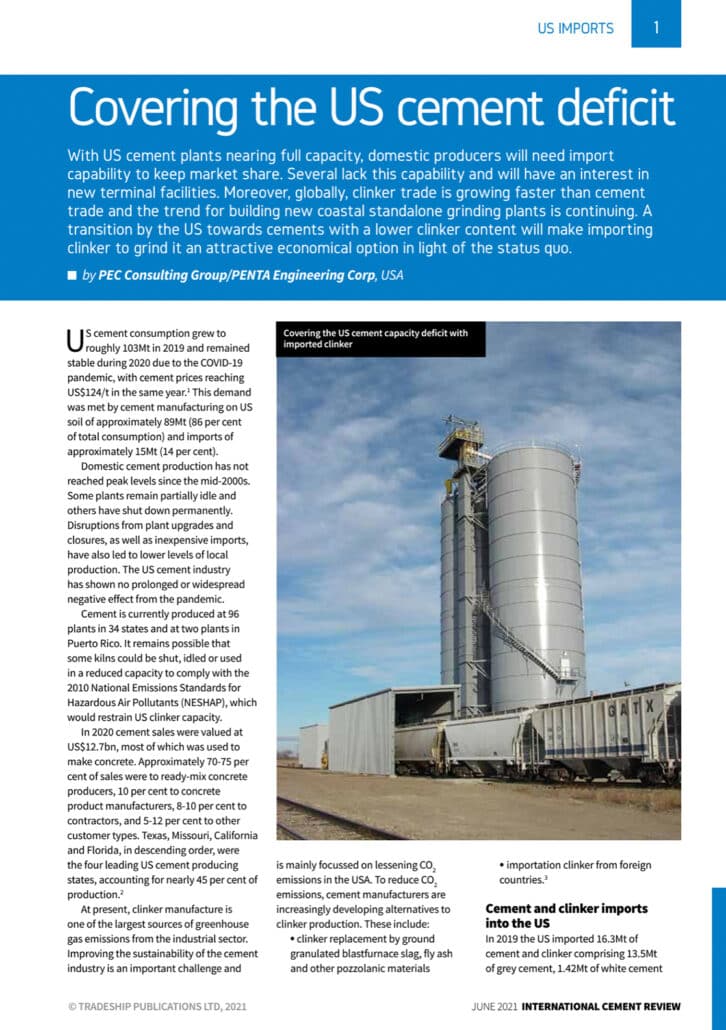

Import Clinker Grinding Systems

Import Clinker Grinding Systems to meet US cement market demand

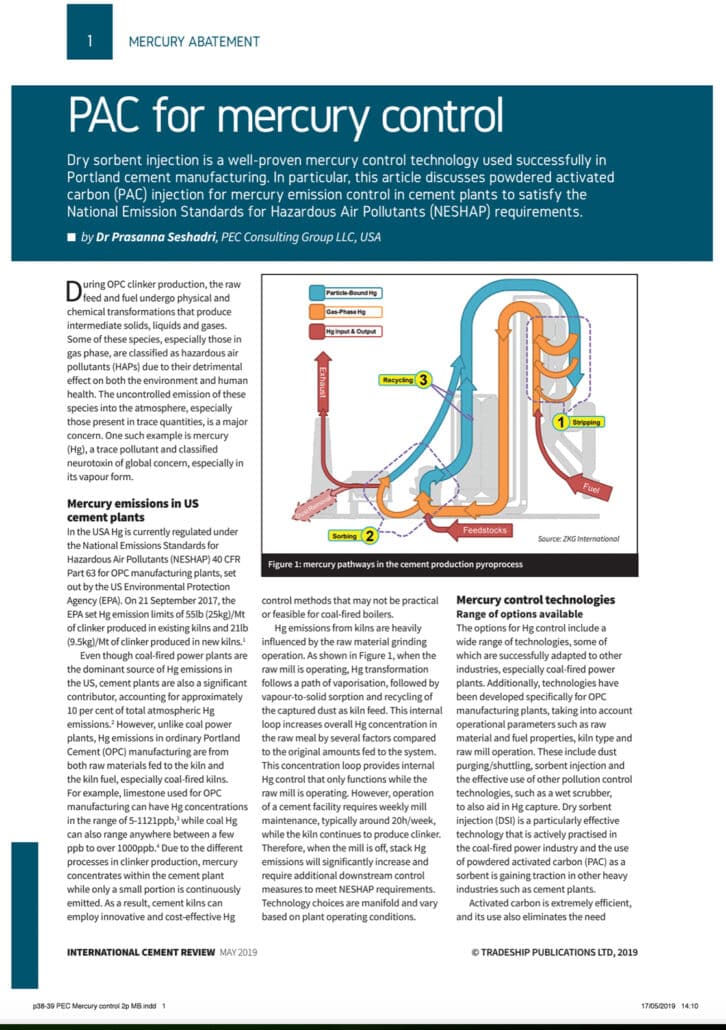

Mercury control in cement plants utilizing powered activated carbon (PAC) injection

Cement Plant Sulfur Control Techniques for the Portland Cement Association

Selective Catalytic Reduction (SCR) and Selective Non-Catalytic Reduction (SNR) for Nitrous Oxide Mitigation

PENTA

Services

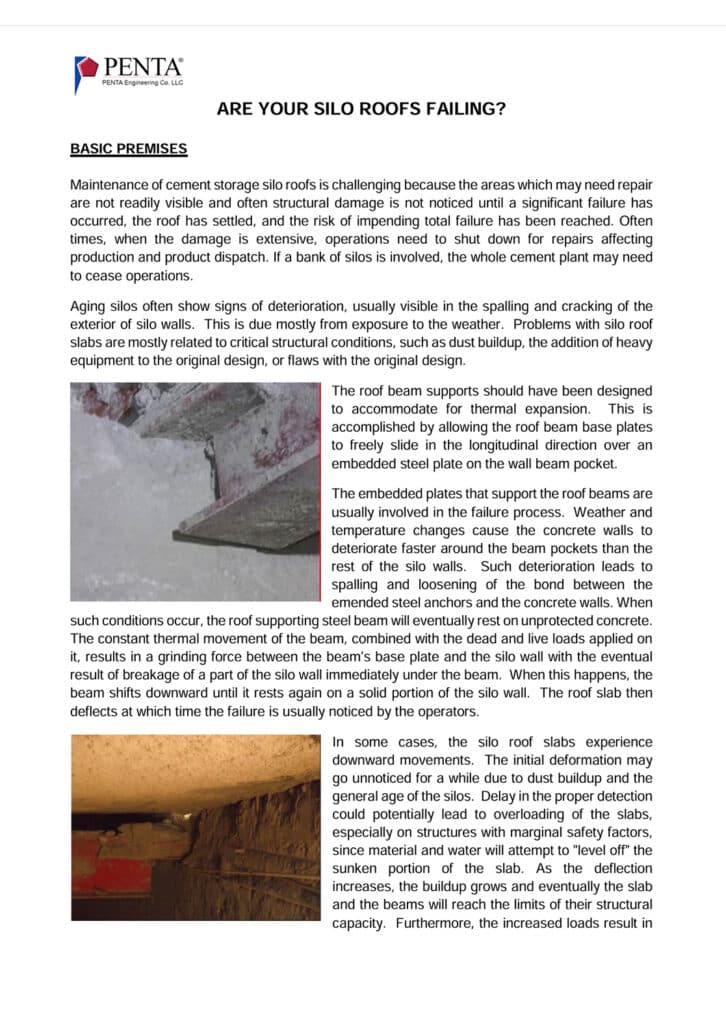

Structural evaluation, recommendation, and remediation/repair guidelines and best practices

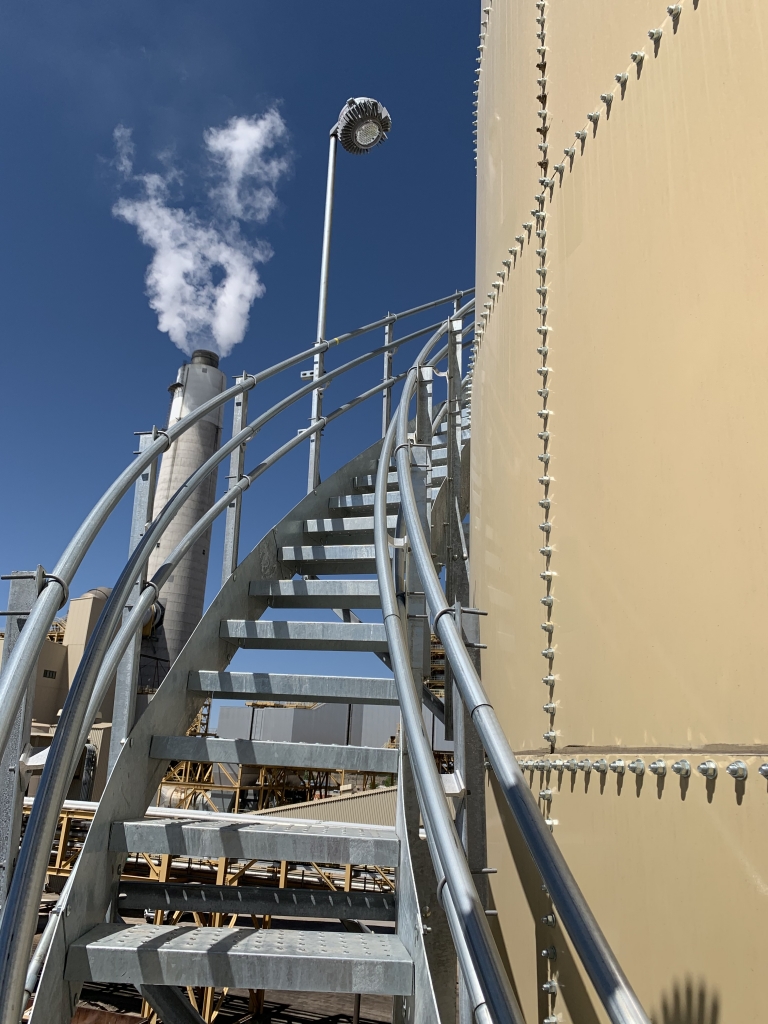

Silo roof structural evaluation, recommendation, and remediation/repair guidelines and best practices

3D scanning capabilities and integration with 3D design process

READY TO LEARN ABOUT OUR EXPERTISE AND SERVICES.

PENTA FEATURED

PROJECTS

Ash Classification System EPCM

A Western United States diversified construction materials group wanted to integrated Type F fly ash into their business to meet ash demand.

EPCM Waste-To-Fuel Facility

PENTA was engaged to develop a waste-to-fuel production facility that produces a fuel source that can be used in calcination as a substitute for fossil fuels.

Tire Derived Fuel Facility

PENTA provided the engineering for the installation of a tire derived fuel (TDF) system at a plant in TX.

READY TO

OPTIMIZE

YOUR INDUSTRIAL

OPERATIONS?

Discover how PENTA’s tailored solutions can solve your toughest challenges. Reach out for expert guidance today.