Industrial Sand

PENTA MARKETS

Industrial Sand

PENTA offers consulting, engineering and EPC/EPCM services to the industrial sand, proppants, mining, and mineral processing industries. PENTA’s team of technical and project professionals have provided efficient, reliable, safe and cost-effective practical project solutions delivering safe plants with predictable operations and maintenance schedules allowing our clients to meet their production and business objectives.

Single-source provider with a proven track record

- Practical engineering designs

- Construction of industrial plants with rigid technological specifications and requirements

- Installation of plant processing systems

- Mining operations designed to meet specific needs

- Consideration given to ease of operation and maintenance

Industrial Sand Services

- Industrial Sand Drying and Screening Plants

- Industrial Sand Resin Coating Plants

- Proppant Transloading Facilities

Complex Logistics Project Solutions

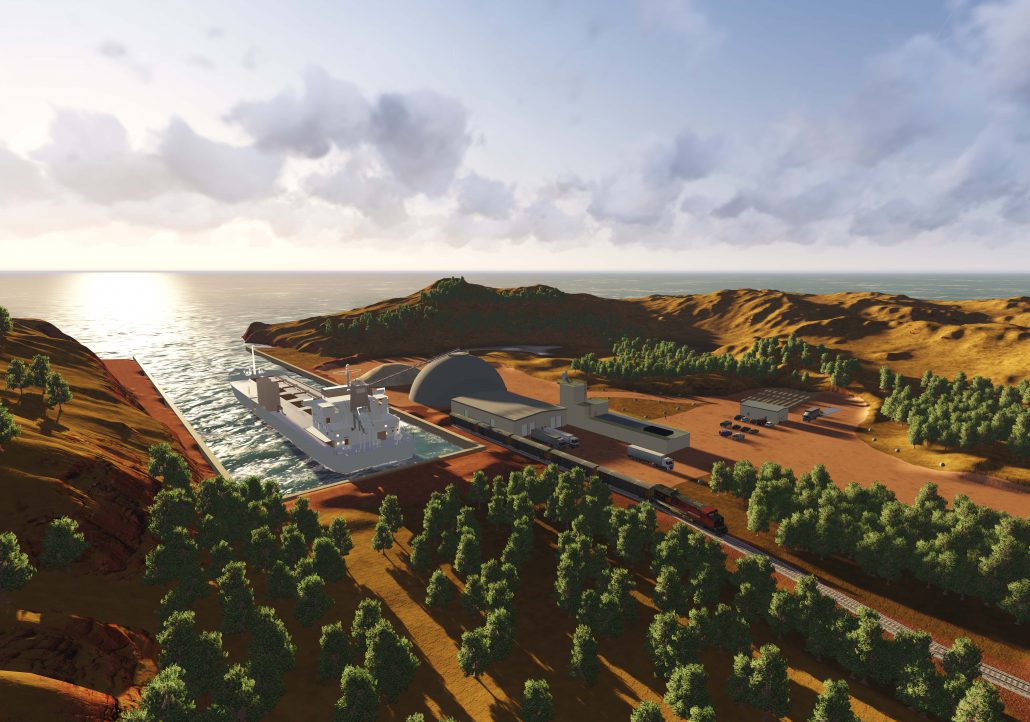

Tackling complex logistics projects is PENTA’s specialty. Every plant is designed and constructed to be energy efficient and minimize operational costs. Key staff have a unique combination of field and engineering experience, so plant considerations include easy equipment maintenance access points,with user-friendly operator interface systems. PENTA’s modular and containerized system solutions have reduced plant downtime during construction and expedited construction schedules.

EFFICIENT SOLUTIONS FOR

GLOBAL Industrial Sand PROJECTS

3D technology is just one way we build industrial plants right the first time so all parties experience minimal risk and desired project outcomes.

PENTA has extensive experience with air pollution control systems and works closely with the Portland Cement Association (PCA) and other relevant industry associations.

PENTA collaboratively works with clients to provide design/build bulk transfer terminal solutions that grow their businesses.

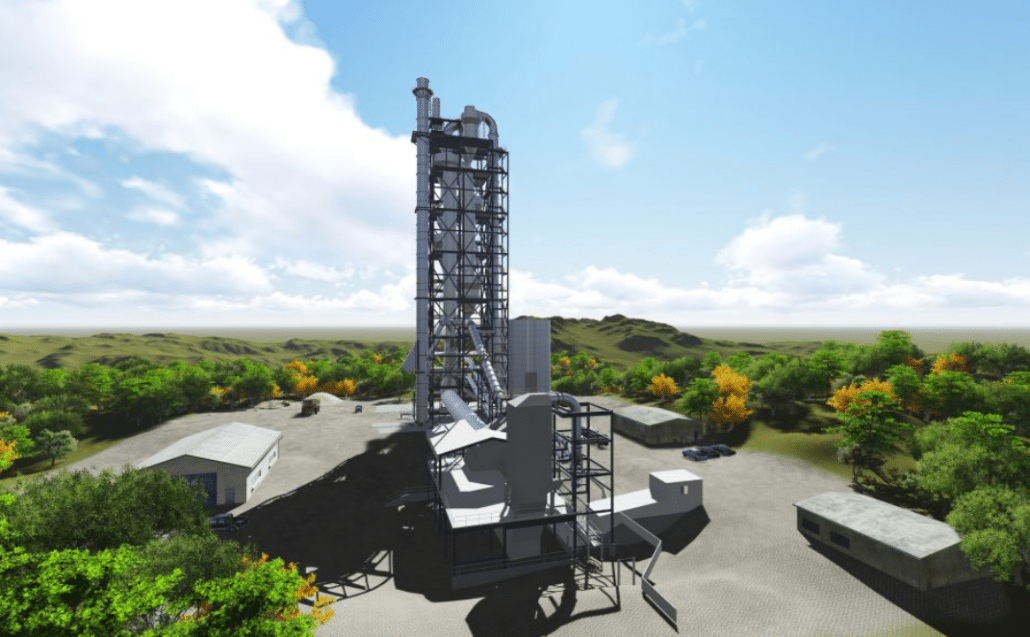

Industrial Sand Drying and Screening Plants

PENTA designs advanced screening plants to maximize ROI. We will design your drying and screening plant to produce a range of proppants to satisfy product requirements. The plants utilize technologically advanced systems and state-of-the-art equipment to operate and meet end-user product specifications.

Sand coating process design includes:

- Sand flow control system

- Heat recovery system to help reduce fuel consumption and optimize the sand temperature control

- Mixer and sand inlet temperature measurement

- Dust tight resin unloading and storage system

- Accurate mixer and additives addition system (max 2% error)

- Mixer and continuous mixer thermal oxidizer emission control system

- Dust collection system

- Raw sand unloading system with automatic sampling and raw sand product inventory

- Rail, truck, and marine load-out systems

- American Conference of Governmental Industrial Hygienist (ACGIH) standards are used for ventilation systems to provide a compliant work environment for employees

Industrial Sand Transloading Systems

Plant transloading systems design and construction includes:

- Optimum systems for loading and unloading materials using industry standards of accuracy.

- Dust collection systems

- Unloaded materials screening system to prevent foreign objects from being transferred into storage silos

- Empty belt unloading conveyor alarm system

- Real-time silo inventory management

- Multi-lane load-out that can accommodate several trucks simultaneously

- Remote and/or local load-out controls

- Automatic bulk storage selection

- Accurate inventory management systems that can be accessed remotely

READY TO OPTIMIZE YOUR CEMENT OPERATIONS?

EXPLORE ADDITIONAL

PENTA SERVICES

RECENT PROJECTS

IKO Announces Plans to Open New Granule Facility in Missouri

Bismarck, Mo (January 8, 2025) — IKO, a global leader in the manufacturing and supply of residential shingles, commercial roofing, and waterproofing products, is proud to announce plans to open

Mining Thickener Tank Detail Engineering

A metal mining operation needed to increase solids in the molybdenum concentrate produced by the existing molybdenum flotation plant in order to optimize operation of an existing larox filter.

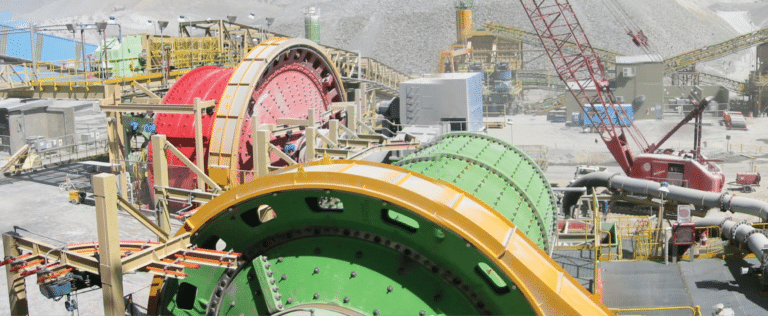

Mining Mill Upgrade Detailed Engineering

A metal mining operation needed to replace an existing wet grinding and classification circuit that was at the end of its operational life with two new Vertimill grinding mills, pumping

READY TO

OPTIMIZE

YOUR INDUSTRIAL

OPERATIONS?

Discover how PENTA’s tailored solutions can solve your toughest challenges. Reach out for expert guidance today.