Alternative Fuels

PENTA SOLUTIONS

Alternative Fuels

PENTA possesses the knowledge and expertise to assist you in evaluating and implementing the use of alternative fuels in your operation.

Our services include:

- Feasibility studies for Waste Processing Systems for using:

- Hazardous and non-hazardous liquids and industrial solids

- Whole or shredded tires

- Sludges

- Municipal Waste

- Refuse Derived Fuel (RDF)

- Development of Alternative Fuel Programs including waste mapping, pyro-process assessment, value chain, pre-processing and co-processing technologies.

- Comparative studies are used to analyze and determine the best technology to process municipal solid waste into RDF.

- Environmental compatibility consultations

- Assessment of impact on environmental emissions and recommendation of potential mitigation measures.

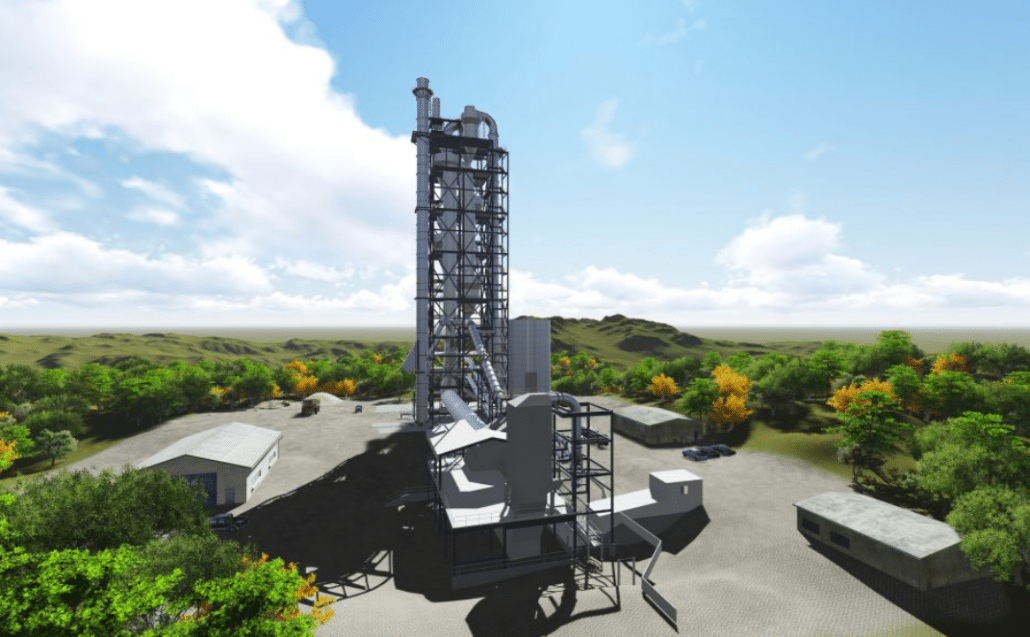

- PENTA designs and installs storage, handling, and combustion systems to utilize various types of alternative fuels with minimum negative impact on the process and chemical composition of your plant’s product.

- EPC/EPCM project implementation including 3D scanning to integrate a new alternative fuels system into existing plant infrastructure, detail engineering, equipment procurement, construction and commissioning.

The primary fuels used in the cement industry have been coal, petcoke, fuel oil and natural gas. There is a wide array of alternative waste fuels that have been successfully used to substitute conventional fuels for pyroprocessing.

Cement, mining, and minerals processing plants present the ideal conditions for use of alternative fuels including: high temperatures, long residence times, an oxidizing atmosphere, ash retention clinker, and high thermal inertia. These conditions ensure that the fuel’s organic part is destroyed and the inorganic part is trapped.

The use of alternative fuels will help conserve non-renewable resources. The wastes used as alternative fuels would most likely have ended up in a landfill or destroyed in dedicated incinerators both of which create the negative consequence of additional emissions. Their use in kilns replaces coal and maximizes the recovery of energy. Employing alternative fuels in cement plants, mining, and other mineral processing facilities is an important element of any sound waste management policy. This practice promotes positive materials recovery and recycling programs.

Using alternative fuels can have a positive impact on the environment by reducing the use of non-renewable energy sources like coal while simultaneously ridding the world of waste products. PENTA takes many factors into consideration when consulting, designing, and/or implementing alternative fuels into any kind of cement, mining, or minerals processing facility. There are many challenges associated with switching from conventional to alternative fuels. Using the production of cement as an example, combustion characteristics of the alternative fuels must be taken into consideration since they can have an effect on the process and quality of the cement. The aim while implementing the use of alternative fuels into your facility is to comply with EPA standards (and other international regulations), to make your facility more environmentally friendly, and to reduce emissions. Yet PENTA is mindful to ensure each project won’t have any kind of negative impact on the quality of the product your facility produces.

EXPLORE ADDITIONAL

PENTA SERVICES

READY TO OPTIMIZE YOUR CEMENT OPERATIONS?

RECENT PROJECTS

Cement Plant Expansion Structural Engineering

PENTA supported a $500+ Million cement plant modernization project in the Midwestern United States providing structural engineering services to an international equipment supplier.

EPCM Waste-To-Fuel Facility

PENTA was engaged to develop a waste-to-fuel production facility that produces a fuel source that can be used in calcination as a substitute for fossil fuels.

Tire Derived Fuel Facility

PENTA provided the engineering for the installation of a tire derived fuel (TDF) system at a plant in TX.

READY TO

OPTIMIZE

YOUR INDUSTRIAL

OPERATIONS?

Discover how PENTA’s tailored solutions can solve your toughest challenges. Reach out for expert guidance today.