Coal Combustion Residuals (CCRs), also referred to as “Coal Ash”, “Ponded Fly Ash”, “Fly Ash”, and “Bottom Ash”, are by-products from the burning of coal to generate electricity in power plants. These by-products are defined as follows:

Fly Ash – a very fine, powdery material composed mostly of silica resulting from the combustion of finely ground coal in a boiler and being drafted by the off-gases into a dust collector.

Bottom Ash – a coarse, angular ash particle that is too large to be carried up into the off-gases, so it drops to the bottom of the coal furnace.

Power plants benefit from the sale of coal ash fly ash that meets ASTM C618 specifications for use as a pozzolanic additive in the preparation of ready-mix concrete. Excess ash not sold has been sluiced and ponded, which has created a negative environmental impact. With stricter EPA mandated regulations for the disposal of coal combustion residuals including water pollution and the diminution of the production of fly ash, a need has been created for the beneficiation of ponded and land-filled ash to a salable product, mostly for the concrete industry. Fly ash and bottom ash can be used in the production of concrete and as a raw material in Portland cement manufacturing.

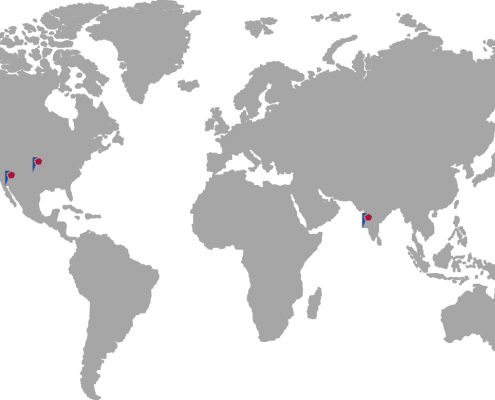

PENTA serves the needs of its clients from source to end user: The power industry and the users or traders of ash.

PENTA has expertise with feasibility and environmental studies, process engineering and logistics. PENTA has designed ash processing systems including all civil, structural, mechanical and electrical engineering, including instrumentation and controls systems, through to detail engineering, as well as distribution terminals. PENTA uses its material handling expertise to design the material handling and storage systems for fly ash from the source Owner’s site to the End User’s site. Projects can be completed on an EPCM or EPC basis.

Case Study

Design of a System to Transport Fly Ash

PENTA performed basic engineering services for the installation of a new fly ash handling system at a power plant to dispatch over one million short tons of dry fly ash per year by rail and truck. Fly ash is currently ponded while it can be sold as a ready-mix concrete additive. The design was prepared accounting for plant operating and logistics requirements.

The fly ash handling system consists of conveying fly ash from existing silos to a new silo capable of loading railcars and trucks simultaneously. The facility includes:

-

- New silo designed with adequate fluidizing air to allow for the transfer of dry fly ash to both the rail cars and trucks

- Bucket elevator, air slide(s), loading chutes, and dust collection equipment

- Associated air locks, flow control valves, and slide gates

- Electrical hardware and controls

- Rail scale and truck scale certified for federal trade

- Associated roads for truck traffic

PENTA’s team performed 3D scanning of the facility and initiated surveying and a geotechnical study. PENTA also prepared the equipment list, equipment and silo specifications, plot plan, P&IDs and General Arrangements; structural and electrical designs; issued bid packages to vendors and subcontractors; evaluated the bids and submitted a report to the Client, which included an EPC CapEx estimate and Project Execution Schedule.