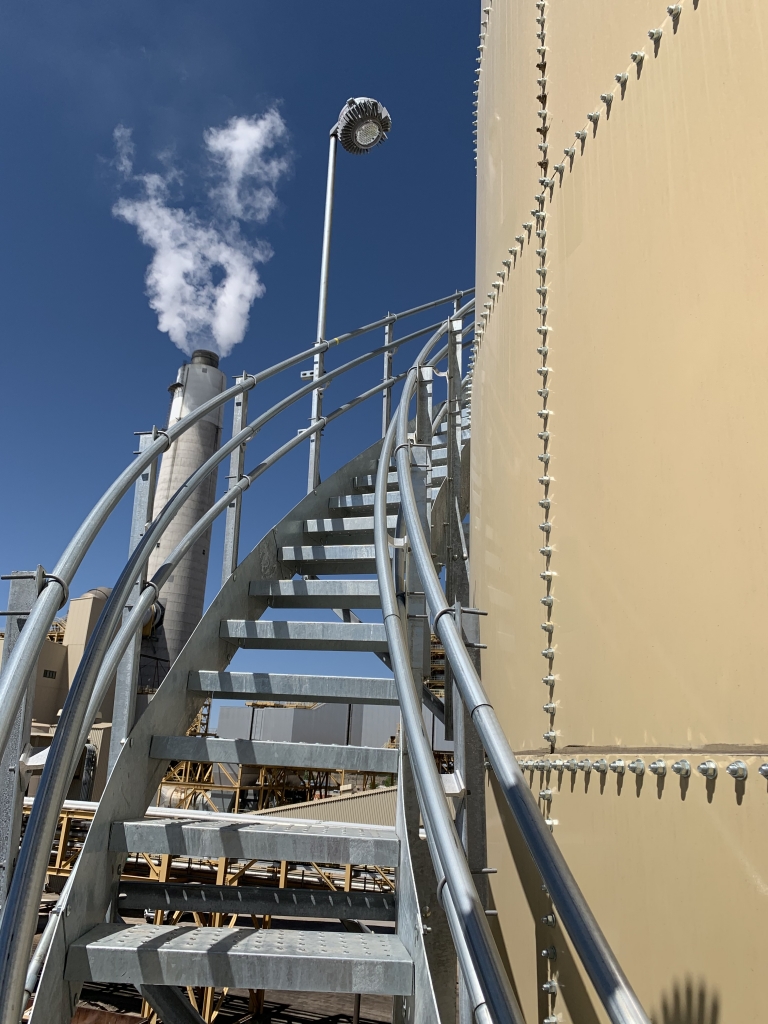

Mining Thickener Tank Detail Engineering

A metal mining operation needed to increase solids in the molybdenum concentrate produced by the existing molybdenum flotation plant in order to optimize operation of an existing larox filter.

A metal mining operation needed to increase solids in the molybdenum concentrate produced by the existing molybdenum flotation plant in order to optimize operation of an existing larox filter.

A metal mining operation needed to replace an existing wet grinding and classification circuit that was at the end of its operational life with two new Vertimill grinding mills, pumping stations, and hydrocyclone classifiers.

A lime industry client wanted to establish a new processing plant at an existing operation to produce a new product to meet market demand.

PENTA supported a $500+ Million cement plant modernization project in the Midwestern United States providing structural engineering services to an international equipment supplier.

A Western United States diversified construction materials group wanted to integrated Type F fly ash into their business to meet ash demand.

PENTA was engaged to develop a waste-to-fuel production facility that produces a fuel source that can be used in calcination as a substitute for fossil fuels.

A copper mining client wanted to increase overall raffinate flow to provide uninterrupted leaching with a safe and efficient pumping and distribution system to a new leach pad.

A client wanted to improve the structural integrity of an existing building in the Southern US and constructed in the 1920s, so it could be used to house a new granulated blast furnace slag grinding plant.

PENTA was engaged by Peabody Coal to provide conceptual and detailed engineering services for overland conveyor system projects at several mine sites.

A gold mining client needed to relocate their 2500stph existing primary crusher to extend quarry life.

PENTA provided the engineering for the installation of a tire derived fuel (TDF) system at a plant in TX.

PENTA provided basic and detail engineering for the installation of a fly ash handling system at an existing power plant to dispatch over one million short tons of dry fly ash per year by rail and truck.

Discover how PENTA’s tailored solutions can solve your toughest challenges. Reach out for expert guidance today.

Corporate Headquarters

10123 Corporate Square

St. Louis, MO 63132, USA

Western United States Office

5151 E Broadway Blvd, Suite 1600

Tucson, AZ 85711, USA

Eastern United States Office

555 North Point Center East

Alpharetta, GA 30022, USA

India Office

Office No. 902 & 903 Ellora Fiesta

Plot No. 8, Sector 11

Opp. Juinagar Railway Station Sanpada, Navi Mumbai 400705, INDIA

© Copyright – Penta Engineering Corporation

"*" indicates required fields