Overview

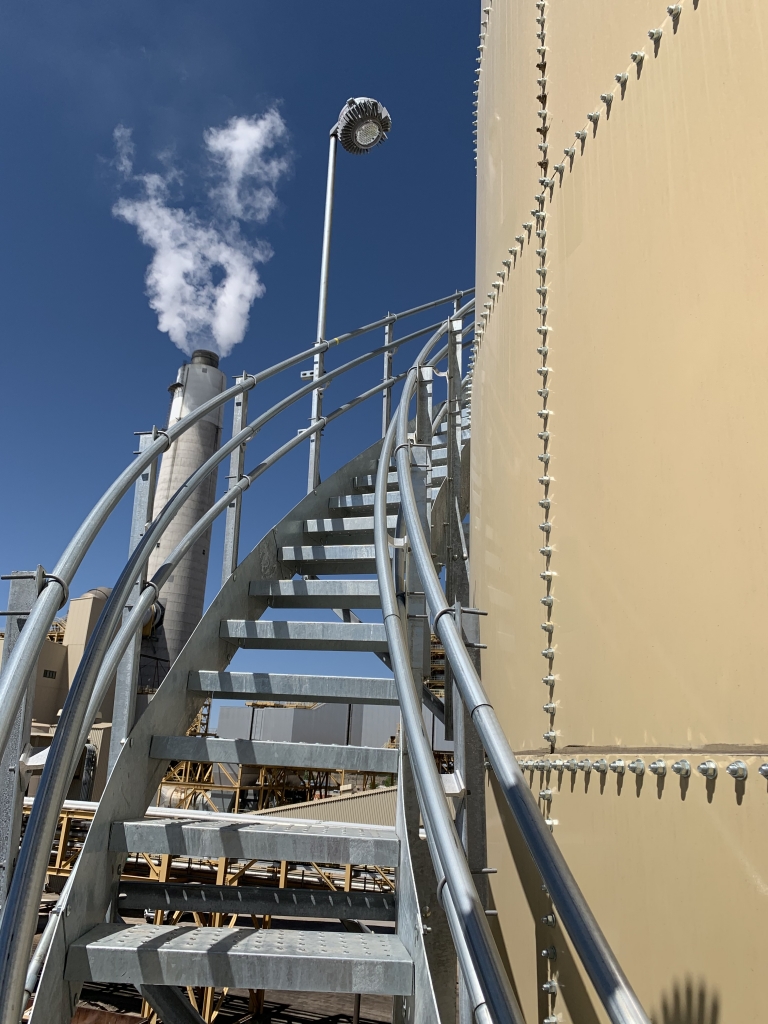

A metal mining operation needed to increase solids in the molybdenum concentrate produced by the existing molybdenum flotation plant in order to optimize operation of an existing larox filter. To achieve the percent solids increase, a new thickener tank with surge tanks, associated piping/pumping systems and electrical upgrades were installed.

Project Scope

- 3D scanning was performed to layout the new system within an existing building eliminating interferences with existing columns/beams and allowing for highly accurate pipe and electrical equipment routing.

- Process engineering including process flow sheet, calculations and sizing of equipment and piping.

- Detail engineering utilizing Revit including mechanical, civil/structural, and electrical engineering. Included demolition drawings.

- Collaborative model reviews with Owner at 30%, 60% and 90% design development.

- Capital cost estimation.

- Procurement support including development of long lead equipment list, as well as obtaining equipment bids/bid tabulation/bid recommendation to Owner. Owner supply chain procured equipment.

- Shop drawing review.

- RFI support during fabrication and construction.

Project Highlights

- Installation inside of existing building. 3D scanning and use of Revit allowed for accurate integration of new system into the existing building and seamless interface between existing and new equipment.

- Engineering packages issued to sequence and align with onsite construction.